HDG Compact 30-149(E)

The HDG Compact 30-149 combines state-of-the-art technology with excellent design and maximum fuel flexibility.

-

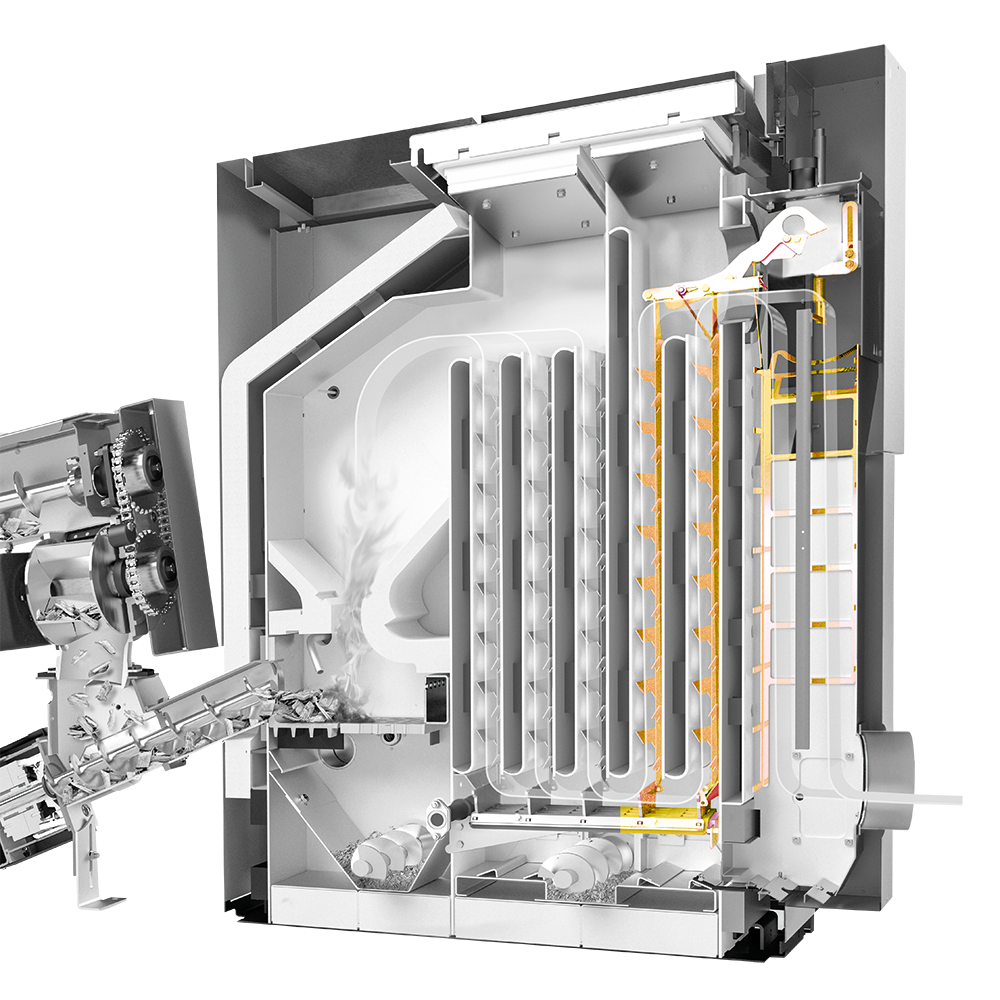

Inside view of the boiler

1

2

3

4

5

6

7

8

1 - Combustion chamber temperature sensor2 - Combustion chamber3 - Tilting grate technology4 - Automatic cleaning system5 - Lambda sensor6 - Automatic ash removal7 - Level monitoring8 - Optional fine dust separator -

Technical data - Compact 30-95(E)

Compact 30(E)

Compact 40(E)

Compact 50(E)

Compact 65(E)

Compact 80(E)

Compact 95(E)

Nominal thermal power (kW) 30 40 50 65 80 95 Minimum thermal power (kW) 9 12 15 19,5 24 28,5 Boiler efficiency at nominal thermal power** 94,5 94,0 93,4 93,3 93,1 93,0 Flue gas temperature at nominal thermal power (°C) 140 150 160 180 160 180 Flue gas mass flow at nominal thermal power* (kg/s) 0,018 0,024 0,030 0,038 0,046 0,053 Water capacity (l) 167 167 167 167 230 230 Operating pressure (bar) 3 3 3 3 3 3 Flue draught requirement (Pa)*** 5 5 5 5 7 7 Maximum operating temperature (°C) 89 89 89 89 89 89 Flue gas pipe connection (mm) 150 150 180 180 180 180 Dimensions and weight

Compact 30(E)

Compact 40(E)

Compact 50(E)

Compact 65(E)

Compact 80(E)

Compact 95(E)

Height without attachments (mm) 1660 1660 1660 1660 1660 1660 Width with VBZ120 and filter (mm) 2060 2060 2060 2060 2385 2670 Depth with container (mm) 1300 1300 1300 1300 1320 1360 Weight (kg) 920 920 920 920 1200 1200 Energy label

Compact 30(E)

Compact 40(E)

Compact 50(E)

Compact 65(E)

Compact 80(E)

Compact 95(E)

Boiler energy efficiency class A+ A+ A+ A+ k.A. k.A. Boiler + controller energy efficiency class (class VI) A+ A+ A++ A++ k.A. k.A. ** Values according to type testing according to DIN EN 303-5 by TÜV-Süd

*** In conjunction with flue gas blower and negative pressure control -

Technical data - Compact 120-149(E)

Compact 120(E)

Compact 130(E)

Compact 140(E)

Compact 149(E)

Nominal thermal power (kW) 120 130 140 150 Minimum thermal power (kW) 36,4 39,7 42 45 Boiler efficiency at nominal thermal power** 95 94,4 94,4 94,2 Flue gas temperature at nominal thermal power (°C) 140 145 160 175 Flue gas mass flow at nominal thermal power* (kg/s) 0,074 0,083 0,088 0,093 Water capacity (l) 357 357 357 357 Operating pressure (bar) 3 3 3 3 Flue draught requirement (Pa)*** 5 5 5 5 Maximum operating temperature (°C) 95 95 95 95 Flue gas pipe connection (mm) 200 200 200 200 Maße und Gewicht

Compact 120(E)

Compact 130(E)

Compact 140(E)

Compact 149(E)

Height without attachments (mm) 1863 1863 1863 1863 Width with VBZ120 and filter (mm) 2706 2706 2706 2706 Depth with container (mm) 987 987 987 987 Weight (kg) 1760 1760 1760 1760 ** Values according to type testing according to DIN EN 303-5 by TÜV-Süd

*** In conjunction with flue gas blower and negative pressure control -

3D view

Impressive in every detail

The new version of the HDG Compact 30-149(E) wood chip boiler combines proven technology with innovative enhancements. The improved PLUS cleaning system, lower purchase costs due to the ash removal now included as standard, as well as faster installation due to complete pre-assembly and reduced number of connections, are the distinguishing features of the latest generation. With the integrated fine dust separator, you can also heat coarse and ash-rich fuel.

In short: From fuel feed to ash removal – the HDG Compact 30-149(E) impresses with many clever solutions down to the smallest detail.

Low emissions thanks to hot combustion chamber

With its particularly high combustion temperatures, the "hot" combustion chamber is the basis for consistently low emissions. The overfill protection with integrated safety shutdown via a heat-resistant stainless steel push-button tube ensures maximum safety during every burning cycle.

Tilting grate technology saves energy

For ash removal, the tilting grate made of solid cast iron is tilted by more than 90 degrees. This removes all combustion residues. Due to the residual glow zone, reignition after closing the tilting grate is often not necessary. This saves valuable energy.

Combustion chamber temperature sensor protects the boiler

The unique combustion chamber temperature sensor ensures steady operation in the optimum power range even with changing material and protects the components by limiting the combustion chamber temperature. Together with the lambda sensor, this also guarantees consistently low emissions.

PLUS cleaning system: Heat exchangers always swept clean

The new, movable turbulators clean all heat exchanger surface areas even more thoroughly and thus ensure constant heat transfer at all times. Thanks to the new drive mechanism around the cool, lower area of the boiler, accessibility has also been improved and the life expectancy increased.

Automatic ash removal for maximum convenience

Ash removal augers convey all combustion residues (combustion chamber, fly chamber and filter ash) fully automatically into the ash containers. There, the ash is compressed in the large-volume ash containers – this guarantees extremely long emptying intervals.

Practical ash box with Euro interface

The new ash container with Euro receptacle from HDG can be transported directly with any standard tractor. The advantages: The mechanical drain saves time and money, the huge filling volume (230 litres) reduces the emptying intervals.

Practical ash box with Euro receptacle

The new ash box with Euro pick-up from HDG can be transported directly with any standard tractor. The advantages: Mechanical emptying saves time and money, the huge filling volume (230 liters) reduces the emptying intervals.

Video of the HDG Compact 30-149(E)

Find out how easy it is to heat with the HDG and experience our flexible wood chip boilers as used by our customers.

Use the entire tree with HDG!

Until now, burning wood chips from branches, treetops and thinning wood has been difficult. Things are different with HDG: Thanks to the Vario delivery system and integrated fine dust separator, coarse and ash-rich fuel can now also be used.

Integrated fine dust filter

With our fine dust separator technology, fuels rich in ash can also be used. Due to the integration in the boiler, only 5 cm more space is required. All fine dust particles are cleaned and collected fully automatically and conveyed to the central ash container just like the other combustion residues.

The advantages:

- Use of high-ash fuels from forest residues

- Electrostatic separator guarantees lowest fine dust values – from heating up

- until burn-out

- Thanks to complete integration in the boiler only about 5 cm

- additional space required

- Fully automatic cleaning system of the electrode and separator surfaces

- Integrated filter ash removal of all residues into the ash container

- Low flue gas pipe connection – ideal for existing fireplaces